Tensometric weighing trolleys

Using, device and principles of functioning

LLC Stromizmeritel specializes in the development and manufacturing of a diverse range of transport and electric weighing trolleys, offering various levels of automation. These trolleys are specifically designed for efficient mass measurement and transportation of numerous components.

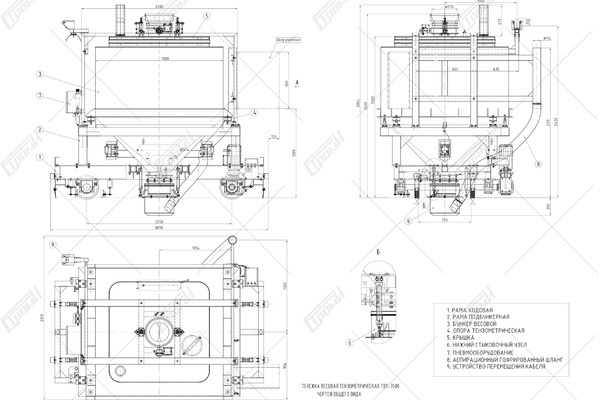

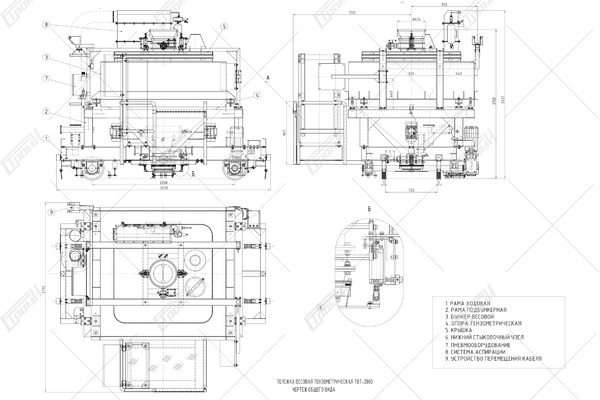

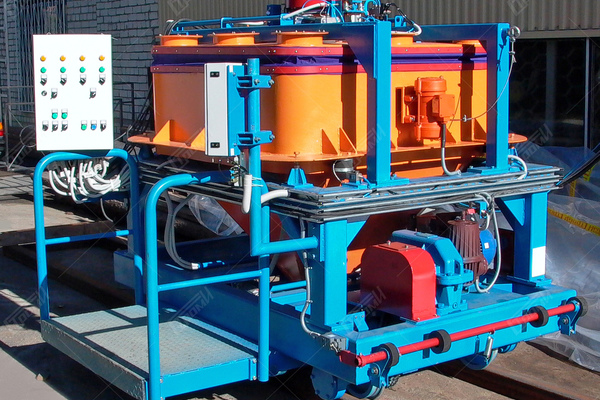

The electric weighing cart serves as a comprehensive mobile weigher, comprising a supportive frame with wheels and an electric drive system, a receiving hopper equipped with a discharge gate, an operator platform featuring control equipment, and a weighing system based on strain gauges. To ensure optimal operations, the cart can be outfitted with sealing coupling assemblies that prevent material dusting during loading into the weighing hopper and subsequent unloading into the mixer. Additionally, the cart can be equipped with an aspiration filter, a compressed air receiver, and pneumatic drives for coupling mechanisms and disk butterfly valves installed on the cart. This configuration significantly reduces the overall number of line drives, particularly in cases where numerous flow bins and multiple discharge positions of raw material components are involved.

The entire process of preparing multicomponent mixtures is closely monitored on the screen of a dedicated monitor, while the configuration and adjustment of the charge recipe are easily performed using the keyboard of a personal computer. All relevant technological parameters are meticulously recorded, archived, and can be readily transmitted to the personal computers of technologists or workshop managers when necessary.

These versatile carts find extensive application in composite shops within glassworks for the production of glassware, exclusive and medical containers, fiberglass, as well as in the manufacturing of refractory mixtures, electrode charge production lines for carbon-graphite electrodes, and for weighing and transporting crushed silicate blocks.

technical specifications

| Parameters | TVT – 1000 | TVT – 2000 | TVT – 3500 |

|---|---|---|---|

| Maximum weighing limit, kg | 1000 | 2000 | 3500 |

| Lowest weighing limit (NmPV), kg | 1000 | ||

| Hopper capacity, m3 | 1,2 | 2,4 | 3,8 |

| Carrying capacity, kg | 1200 | ||

| Weighing error over the entire range, kg | 1,0 | 1,0 | 1,0 |

| Type of strain gauges beam | beam, BSA-1T | beam, BSA-1T | beam, H8C-1,5t-4B |

| Number of strain gauges of hoppers with mixer consumables | 4 2 - 22 1 - 9 | 4 | 4 |

| Type of control system | automated electro-pneumatic | electro-pneumatic control | electro-pneumatic control |

| Electrical supply, V | 380 ± 38 | 380 ± 38 | 380 ± 38 |

| Utility frequency, Hz | 50 ± 1 | 50 ± 1 | 50 ± 1 |

| Pneumatic supply, MPa | 0,5 – 0,8 | 0,5 – 0,8 | 0,5 – 0,8 |

| Maximum travel speed, m/s | 1,5 | 0,63 | 0,63 |

| Maximum allowable acceleration, m/s2 | 0,66 | 0,25 | 0,21 |

| Overall dimensions (length x width x height), mm | 2750 x 2624 x 2471 | 3078 x 2728 x 2441 | 3078 x 2313 x 3207 |

| Weight, kg, max | 1950 | 2790 | 2700 |