Crushers for non-abrasive clumping materials

USING

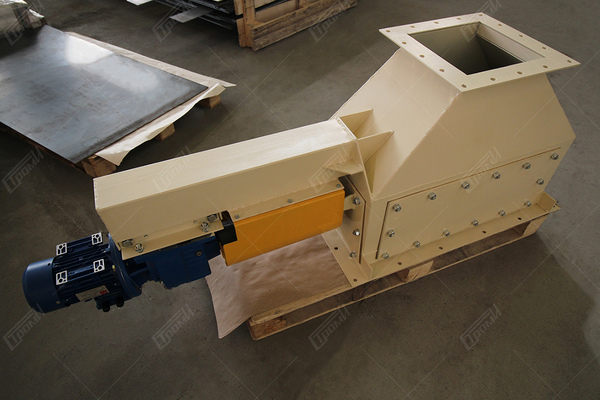

The crusher is designed for chopping of less-abrasive materials, prone to caking, for example sodium carbonate, with humidity max. 3% before feeding into conveying equipment in production rooms with ambient temperature from -10° to 50°. Actual capacity depends on the processed material properties, chopping conditions and is specified when designing the crusher.

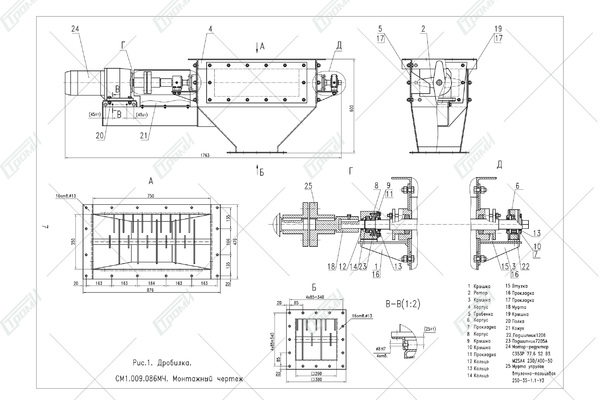

Design of the crusher

The crusher consists of the following parts:

– a body, manufactured of sheet material, inside of which a rotor is installed, fixed in the bearing units

– a comb, which is fixed on the body wall with bolts

– a gear motor, connected to the rotor by a pin coupling

Operation principle

Material for chopping is fed through the loading flange in the crusher body between the comb and rotor edges. During the rotation of the rotor the material is crushed between the edges of the comb and rotor and runs into the discharge hopper.

technical specifications

| Parameters | Values |

|---|---|

| Capacity, kg/hour | 4000* |

| Size of pieces of the processed material, max, mm | 250 |

| Size of particles after chopping, mm | 10...15 |

| Rotor rotation frequency, rpm | 18 |

| Size of the rotor blades, mm | 280 |

| Size of the unloading tray, mm | 260 х 260 |

| Type of the gear motor | С353Р 77,6 S2 B3 M2SA4 |

| Electric power supply voltage, V | 380 |

| Consumed power, kW | 0,75 |

| Overall dimensions (L х W х H), mm | 1763 х 476 х 600 |

| Weight, max, kg | 82 |