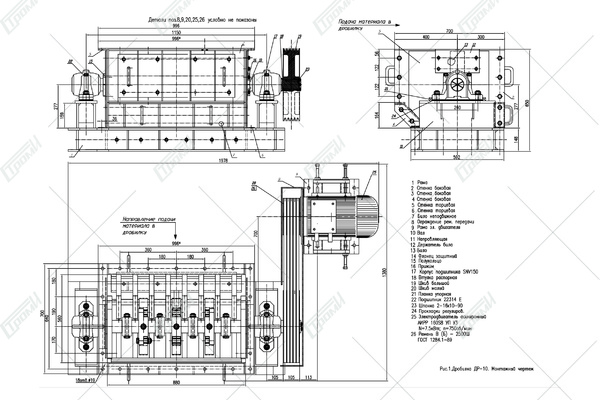

Rotary crusher DR-10

USING

The rotary crusher, hereinafter referred as the crusher, is designed for crushing of different lump materials and can be used in mining and metallurgical industry, as well as in production of building materials before feeding into conveying equipment in production rooms with ambient temperature from –5° to 40°.

DESIGN AND OPERATION PRINCIPLE OF THE ROTARY CRUSHER

Crusher DR-10 consists of the following units:

– a frame, on which the crusher body with the driven shaft fixed on bearing assemblies are mounted. Rotation to the shaft is transmitted by means of a big wheel through a V-belt transmission from a small wheel, installed on the electric motor shaft. Holders with impact bars fastened by means of bolted joints are mounted on the driven shaft

– an electric motor installed on a separate frame.

The body of the crusher consists of side and end walls connected to each other by means of bolted joints. Inside the body immovable impacts bars are fixed to the walls by means of bolts.

Material for crushing is fed through the input gate in the crusher body between the moving and fixed impact bars. When rotating the driven shaft the material is intensively crushed by blows of the moving impact bars to material. Further the crushed material is unloaded through the output gate of the crusher. The crusher operation is controlled by means of a control unit.

technical specifications

| Parameters | Values |

|---|---|

| Capacity, tons/hour | 6…10* |

| Compression strength of the incoming material, min, MPa | 320 |

| Lump size of the processed material, max, mm | 250 |

| Grain size after crushing, mm | 20...30 |

| Number of moving impact bars and pitch, pieces/mm | 7/105 |

| Number of fixed impact bars and pitch, pieces/mm | 16/75 |

| Rotation frequency of the driven shaft, rpm | 375 |

| V-belt transmission ratio | 2 |

| Motor type | AIRR 160S8 UP U3 |

| Power supply voltage, V | 380 |

| Consumed power, kW | 7,5 |

| Overall dimensions, mm | 1380 х 700 х 630 |

| Weight, max, kg | 800 |