Glass mass scraper granulators

USING

Glass mass scraper granulator is specifically designed for granulation and transportation glass mass from the glass-forming machines in both horizontal and inclined directions.

It operates as a two-level scraper conveyor located within a water bath, supported on special rails, where the pelletized glass mass is introduced.

The glass mass granulator is a continuous-action mechanism that operates within an air temperature range of 1 to 40ºC.

In situations where maximum capacity results in a high mass discharge, the water temperature in the glass feeding area may reach the boiling point. In such cases, the customer should activate the additional water supply to the granulator.

DESIGN OF THE GRANULATOR

The glass mass granulator is a product that is assembled on-site at its place of operation. It consists of the following main assemblies and components:

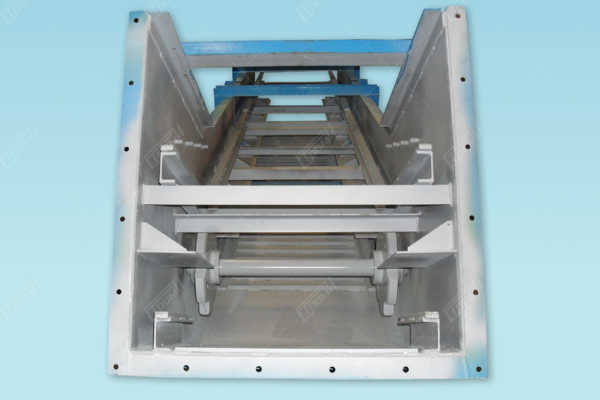

Trough is the primary unit of the glass mass granulator and is composed of separate intermediate sections as well as a rotary section that is hermetically welded together. Inside the trough, there are two levels with parallel guide bars. A traction device, comprising of traction chains with attached scrapers, moves along these guide bars. Protective screens are positioned above the guide bars along the entire length of the water bath to prevent glass pellets from falling onto the chains.

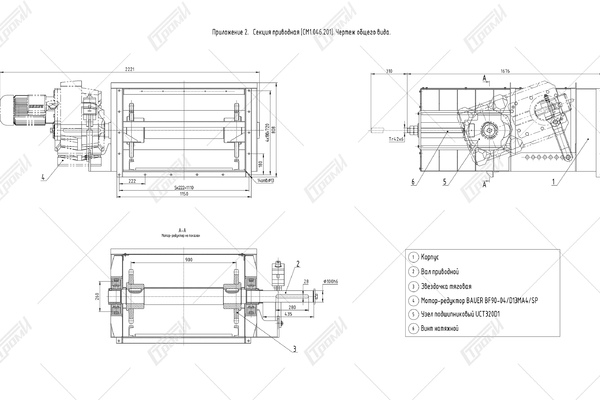

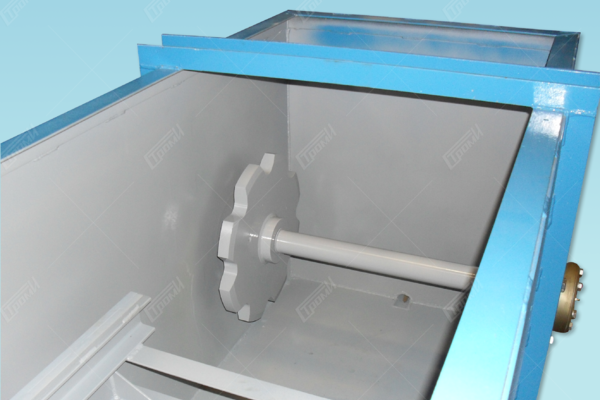

Drive section includes a housing, a drive shaft with two sprockets, two bearing assemblies combined with a tensioning mechanism, a gear motor with a hollow shaft and torque arm, and a hopper for discharging the pelletized glass.

End section consists of a body, an end shaft with two sprockets, two bearing assemblies, and a water drainage pipe. The end section facilitates a 180º change in the direction of movement for the working body of the glass mass granulator.

To facilitate the transition of the traction body from the horizontal part of the tub to the inclined section, the glass mass granulator tub is equipped with a pivoting section. This section consists of a housing, a shaft with deflecting sprockets, two bearing assemblies, and profile guide bars. The lower branch of the chain changes its direction of movement by passing through the deflecting sprocket, while the upper branch wraps around the profiled guide bar. An intermediate section is positioned between the drive section and the pivoting section.

To control the movement of the scrapers, the glass mass granulator is equipped with a circuit breakage control unit that incorporates a non-contact sensor.

Additionally, the package includes an overflow unit that needs to be installed during erecting works.

The tub structure is protected against abrasive wear by maintaining a suitable gap between the scraper and the bottom of the tub. This gap prevents excessive movement of the glass mass at the bottom, thereby minimizing abrasive wear on the metal structure.

THE PRINCIPLE OF FUNCTIONING

The glass mass enters the upper level of the glass mass granulator bath, where it is transported by the scrapers towards the end section. Subsequently, the glass mass descends to the lower level and continues to be conveyed towards the drive section. As the glass mass is transported through the water environment, it cools and is fragmented into pellets before reaching the discharge area of the drive station.

Please note that due to continuous efforts to improve equipment design, there may be changes that do not impact the quality of operation but are not reflected in the operational documentation.

technical specifications

| Parameters | Values |

|---|---|

| Bath width of the glass mass granulator, mm | 1040 |

| Tub height of the glass mass granulator, mm | 895 |

| Scraper width, mm | 806 |

| Length of the horizontal section of the glass mass granulator, mm | 22950 |

| Length of the inclined section of the glass mass granulator, mm | 4965 |

| Length in plan along the axes of the drive and end shafts, mm | 30185...30453 |

| Height to pellet discharge level, mm | 2946 |

| Scraper speed, m/min | 8,14 |

| Drive sprocket speed, rpm | 6,2 |

| Highest output, t/h | 12 |

| Traction chain type | plate traction chain M224-2-160-1 GOST 588-81 |

| Gearmotor type | BAUER BF90-04/D13MA4/SP or equivalent |

| Type of tensioning device | screw, 310 mm |

| Power supply voltage, V | 380 |

| Nominal power, kW | 7,5 |

| Dimensions (L х W х H), mm | 31,28 х 2,37 х 3,54 |

| Weight, kg, no more than | 16000 |