Turning gears for dropping glass drops

Using, device and principles of functioning

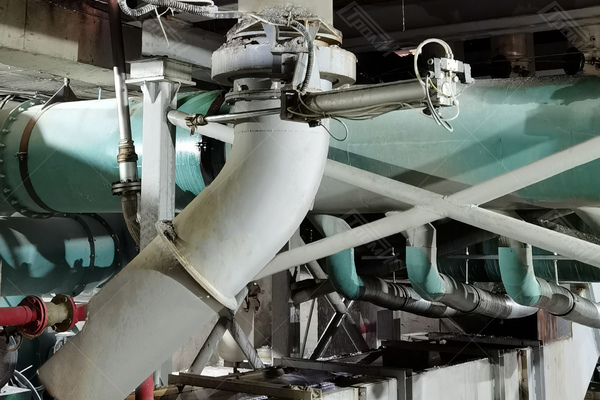

The drop chute swivel mechanism serves the purpose of discharging the molten glass mass in the form of droplets into either a glass granulation unit or a mobile container. The control of this mechanism is fully automated, ensuring efficient and precise operation.

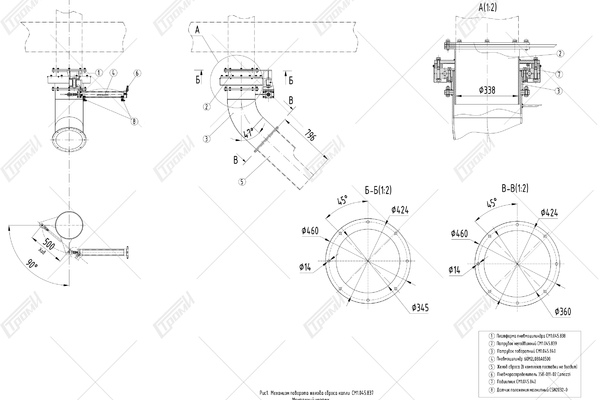

The turning mechanism comprises several key components, including a pneumatic cylinder platform, a stationary branch pipe, a rotating branch pipe, and a bearing that enables the rotating branch pipe to rotate 90 degrees around the stationary branch pipe. The pneumatic cylinder is securely attached to the platform using a swivel bracket, and its rod is connected to the swivel branch pipe. To facilitate the attachment of the glass mass discharge chute (not included in the delivery set), a flange connection is utilized between the swivel branch pipe and the chute. Magnetic sensors are integrated into the pneumatic cylinder to monitor the position of the piston rod, ensuring accurate control of the extreme positions of the branch pipe.

The pneumatic equipment consists of an air preparation unit, a pneumatic distributor, fittings, and pneumatic tubes.

Upon receiving an electric signal, the pneumatic valve solenoid opens, allowing air to enter the corresponding cavity of the pneumatic cylinder. As a result, the pneumatic cylinder rod moves from one extreme position to another, precisely turning the mechanism to the desired orientation for discharging the glass into a container or a glass mass granulator.

technical specifications

| Parameters | Values |

|---|---|

| Nominal bore, diameter, mm | 340 |

| Angle of rotation° | 90 |

| Сontrol | electropneumatic |

| Pneumatic power must be supplied from a pressure network, MPa | 0,5 ± 0,1 |

| Air consumption per cycle (double stroke), reduced to normal pressure, l | 25 |

| Air flow rate, m3/min | 0,3 |

| Requirements for cleaning and drying compressed air according to GOST 17433-80, class | 7 |

| Pneumatic cylinder diameter, mm | 80 |

| Stroke of pneumatic cylinder rods, mm | 500 |

| Electrical power must be supplied from an alternating current network with voltage, V | 220 ± 22 |

| Frequency, Hz | 50 ± 1 |

| Degree of protection of electrical equipment enclosures | IP54 |

| Power consumption, kW | 6,5 |

| Weight, kg, not more than | 200 |

| Ambient temperature° | 5...40 |