Big-bags unloading stations SRB

USING

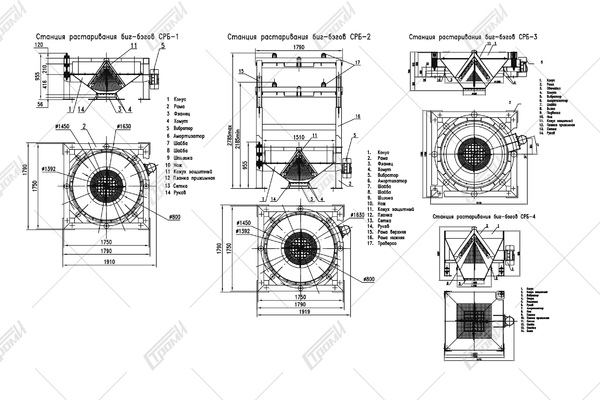

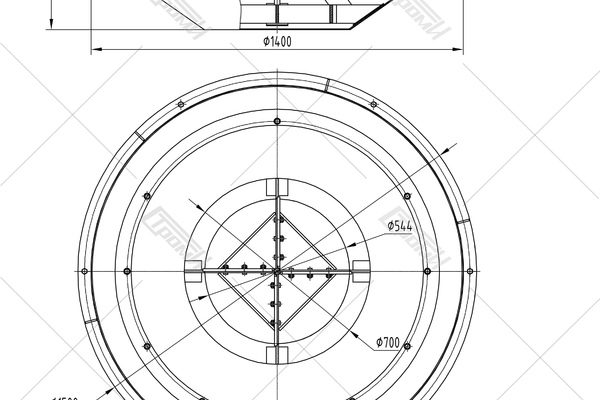

The big bags unloading station SRB-1 consists of a frame, a conic receiving hopper with a rubber packing and a grid for lumps holdup, knives for big bags cutting and an unbalanced mass vibration generator. In the process of unloading at SRB-1 a big bag is held by a lift and transfer mechanism that’s why the unloading of different materials is performed sequentially. For parallel unloading of several big bags the unloading station SRB-2 is used, the structure of which includes an additional frame, adjustable for height and cross traverse, to which a big bag is fixed. The presence of a traverse allows using the lift and transferring mechanism for other operations after the big bag is fixed for unloading. The station SRB-4 has smaller dimensions and is recommended for usage in space-limited process plants. Big-bags unloading station SRB-5 is designed for uniform supply of bulk materials from big bag into storage bins or transport units. The material in the bags must be conditioned and it must satisfy specifications.

technical specifications

| Parameters | SRB-1 | SRB-2 | SRB-3 | SRB-4 | SRB-5 |

|---|---|---|---|---|---|

| Big bag volume, m3 | 1,2 | 1,2 | 1,2 | 1,2 | 1,2 |

| Loading shell size, mm (feeding hole diameter – D1, discharge hole diameter – D2) | 1390 | 1390 | 1390 | 1200х1200 | D1 700, D2 544 |

| Power supply voltage, V | 380 ± 38 | 380 ± 38 | 380 ± 38 | 380 ± 38 | 380 ± 38 |

| Consumed power, kW | 0,62 | 0,62 | 0,55 | 0,62 | 0,62 |

| Weight, kg, max | 470 | 1500 | 470 | 280 | 150 |

| Limit load, kg | 1000 | 1000 | 1000 | 1000 | 1500 |

| Ambient temperature° | 5...40 | 5...40 | 5...40 | 5...40 | –30...40 |