Screw feeders and conveyors

Design and function

Screw feeders and screw conveyors are used for moving free-flowing, poorly flowing and caking materials with different physical and chemical properties. Screw feeders are mainly used as charging und discharging units of different weighing batchers, air-actuated pumps and other equipment. Special screw structures, multi-speed work mode and a shut-off sealing flap at the outlet allow ensuring by means of the screw feeders the minimum dosing errors at high efficiency. Dosing of water-absorbing ingredients of glass mixture, which are prone to adhering to screw blades, is done by means of the two-shaft screw feeders with mutual cleaning of screw surfaces. The cases of the screw feeders are mainly made of steel pipes of different diameter.

The screw conveyors usually have a channeled case and differ from the feeders by a strengthened screw structure. They are equipped with a high-powered drive with increased load capacity, what allows operating such conveyors with full interturn rooms and big angles.

Apart from manufacturing the conveyors of usual industrial configuration we produce screw conveyors of stainless steel as well as abrasion-resistant and heat-resistant conveyors. Manufacturing of the reversible and turning screw conveyors distributing the conveyed material among several feed bins or silos is possible.

technical specifications

| Model | Capacity, m3/h | Screw diameter, mm | Length of conveying, m | Drive power, kW |

|---|---|---|---|---|

| PS – 28 | 0,03 | 28 | 0,32 | 0,37 |

| PV – 47 | 0,10 | 47 | 0,32 | 0,37 |

| PV – 75 | 1,20 | 75 | 0,52 – 2,50 | 0,75 – 2,2 |

| KVS – 125 | 3,60 | 125 | 0,60 – 4,0 | 2,2 |

| KVS – 200 | 7,50 | 200 | 0,8 – 4,0 | 3,0 |

| KVS – 250 | 12,00 | 250 | 1,0 – 4,0 | 4,0 |

| KVS – 315 | 36,00 | 315 | 1,00 – 6,00 | 5,5 – 9,0 |

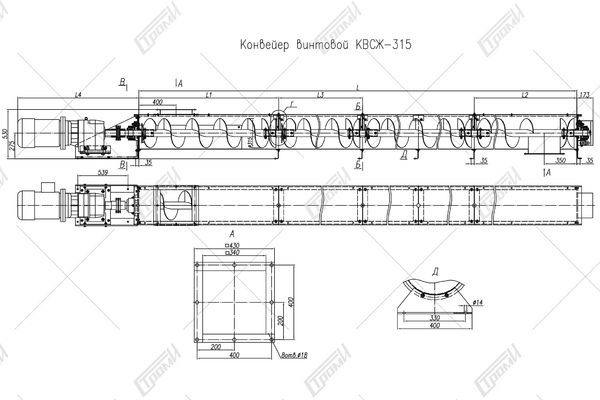

| KVSZH – 315 | 40,00 | 315 | 3,00 – 30,00 | 2,2 – 15,00 |

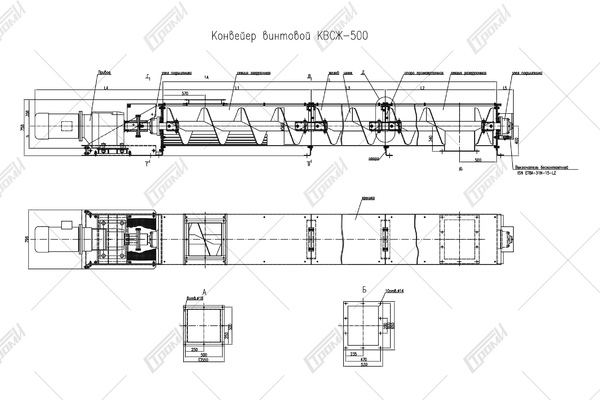

| KVSZH – 500 | 95,00 | 500 | 4,0 – 21,00 | 5,5 – 30,0 |