Swinging feeders

USING

The swinging feeder PТК-500 is designed for uniform feeding of granular and chunky materials with a fraction size of no more than 250 mm and a bulk density of no more than 2.5 g/cm3 from hoppers and other containers into production or transportation equipment with a specified capacity in production facilities at an air temperature ranging from -30° to 50°. The specified capacity is given for gravel (or crushed stone) with a moisture content of no more than 5%, assuming that the material flows without hanging and the hopper is properly constructed. The actual capacity should be clarified specifically depending on the operating conditions, characteristics of the transported cargo and other factors.

Design and function

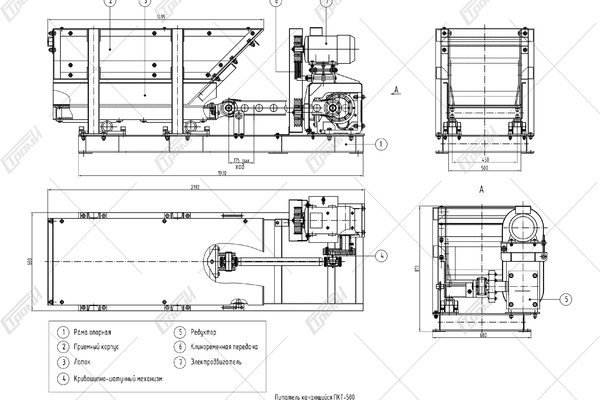

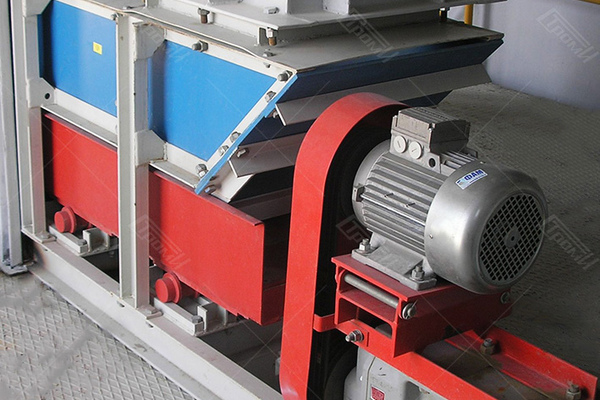

The swinging feeder comprises the following components:

– support frame

– wear-resistant steel-clad receiving housing, securely attached to the frame

– tray with wear-resistant steel lining and a protective cover, seamlessly gliding on supporting rollers

– crank-slider mechanism enabling the smooth reciprocating movement of the tray

– crank drive reducer

– v-belt transmission

– electric motor

The feeder operates on a simple yet effective principle: as the tray moves towards the discharge point, the material efficiently fills the vacant space within the receiving housing. Upon the reverse movement, the loaded material and its support against the rear wall of the housing create resistance, allowing the tray to slide relative to the material placed on it. Consequently, the material is smoothly discharged through the tray's edge and into the designated receiving device, such as a funnel.

To optimize the feeder's performance and regulate the tray's movement, a rotating crankshaft disc is utilized, which in turn adjusts the transmission lever responsible for rotating the crankshaft housing and facilitating the movement of the connecting rod linked to the tray.

technical specifications

| Parameters | Values |

|---|---|

| Width, mm | 500 |

| Length, mm | 12...175 |

| Frequency of the tray's double-trip (at the rotation frequency of the motor), rpm | 39 (1420) |

| Capacity, m3/h | 70 |

| Type of motor | AIR100L4380V 4 kW (1500 rpm) |

| Type of gearbox | UD-K77AD3-35, 2-M1 side B |

| Electric energy input, kW | 4,0 |

| Power supply voltage, V | 380 |

| Feeder weight, kg, no more | 580 |