Vibrating screens

USING

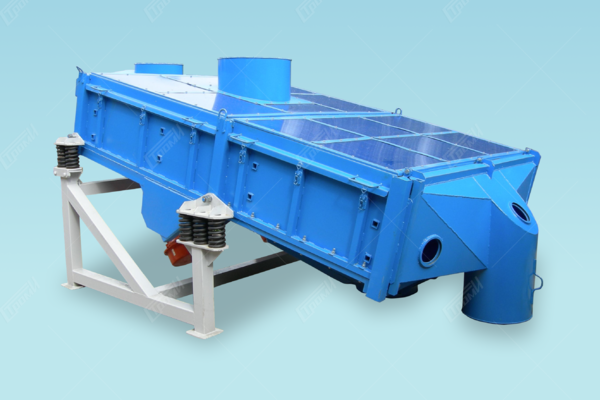

Vibrating sieves Н20 are designed for division of bulk granular materials of small and medium abrasive ability with bulk density up to 2000 kg/m3, depending on model, into several grain-size classes. Actual capacity depends on the incoming material properties, standard size of grids of the sieving surfaces, adjustment of vibrators eccentric mass position, operating conditions and should be specified when ordering the equipment. Sieve mesh area size also specifies during equipment order, columns are filled before delivery of equipment.

Design and operation principle

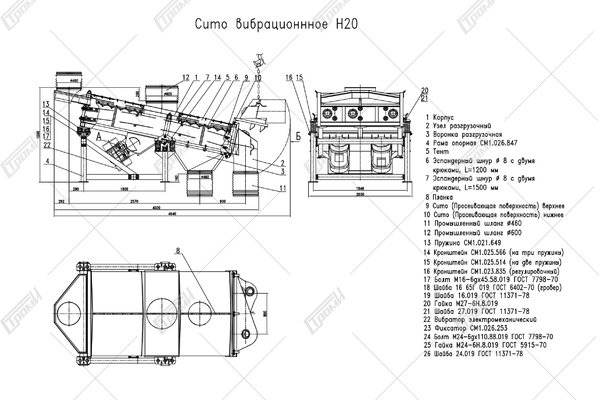

Stromizmeritel LLC produces sieve models Н20, Н10. Sieves divide material into two and three grain-size classes and differ in number of sieving surfaces.

Sieves Н20 are vibrating sieves with one-direction reciprocal motion. A system of two electromechanical vibrators with anti-phase rotation of the rotors is used as a vibration exciter. Angle of the sieves body inclination to the horizontal is 12°, vector of the joint driving force from the vibrators operation to the horizontal is 33°.

Supply of the incoming material to a vibrating sieve and withdrawal of the separated fractions as well as aspiration of the sieve interior space are done by means of industrial hoses (crinkled hoses) and collars included into scope of supply.

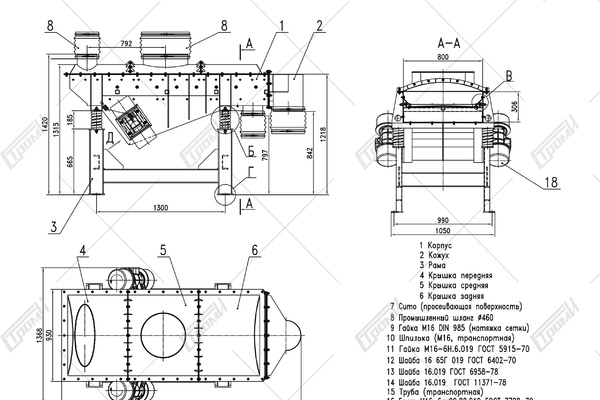

Each sieve Н20 includes the following blocks:

– a body containing a loading throat

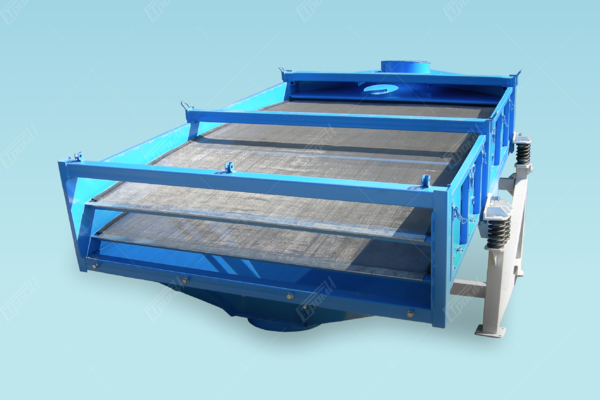

– a discharge unit, receiving and distributing the oversize fraction of the upper and lower sieving surfaces (grids) into correspondent shells. The hinging discharge unit can be thrown upwards for inspection and replacement of grids. For quick inspection of grids during operation there are six round edged hatches, closed by rubber collars (three in the back wall of the body and three in the discharge unit)

– a discharge hopper, receiving the material passed through the grip

– a support frame with springs and brackets for body fixation

A correspondent number of layers of the sieving surfaces (sieves) is located with screw tighteners inside the vibrating sieve body (three tighteners per each sieving surface). Tightening of the sieves is done along the direction of the material travel. In the working tight drawn condition the sieves are bow-shaped surfaces. Additional sieving surfaces increase the sieving efficiency especially it refers to materials with big difference in grain size.

technical specifications

| Parameters | Vibrating sieve H10 | Vibrating sieve Н20 |

|---|---|---|

| Estimate of capacity for dry sand based on the incoming material, t/h, (for dry soda) max | 10 | 20 |

| Incoming pieces size, mm, max | 30 | 30 |

| Humidity of the incoming material, %, max | 0,5 | 0,5 |

| Number of sieving surfaces | 2 | 1 |

| Number of fractions received | 3 | 2 |

| Angle of inclination of the sieving surfaces to the horizontal° | 0 | 16 – 17 |

| Dimensions of the sieving surfaces, mm | 650 х 1580 | 1470 х 2730 |

| Permissible size of meshes of the sieving surfaces in clear, mm | 0,4…10 | 0,4…10 |

| Type of the vibration system | one-directional reciprocating | one-directional reciprocating |

| Amplitude of vibration, mm | 3...5 | 3...5 |

| Vibration frequency, Hz | 25 | 25 |

| Type of electromechanical vibrators applied | MVE 9000/15 OLI Wamgroup, 230/400 V, 50 Hz, 3 phases, 1500 rpm or MVSI 15/9000 S90 Italvibras 230/400B, 50 Hz, 3 phases, 1500 rpm | MVE 2400/15 OLI Wamgroup, 230/400 V, 50 Hz, 3 phases, 1500 rpm |

| Number of vibrators | 2 | |

| Consumed power, kW | 3,2 | 2 х 7,5 (2 х 7,0) |

| Air flow rate for aspiration, m3/hour, max | 1500 | |

| Type of climatic modification as per GOST 15150 | У2 (for placement under a shed and in rooms with ambient temperature from -45° to 40°) | |

| Overall dimensions of the sieve on the frame (L х W х H), mm | 2419 х 1368 х 1420 | 4012 х 2036 х 1680 |

| Weight of the vibrating sieve with the positioning frame, kg | 790 | 2000 – 2060 |

| Weight of the positioning frame, kg | 103 | 180 |

| Dynamic factor | 5 | 5 |