Screening and classification

equipment

APPLICATION

- Screening and grading (classification) of bulk raw components are integral process operations that are performed during the processing of lump dolomite, lump lime stone, sheet and tare crushed glass, refractory materials, salt, slags, mineral fertilizers, etc.

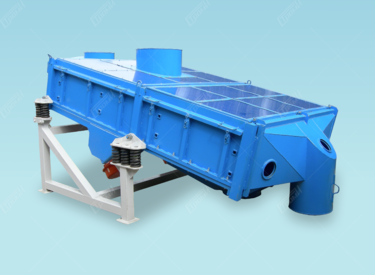

- Unbalanced-throw screens (sorting machines) are designed for separating bulk materials by separation size with pieces up to 50 mm and with a capacity from 10 up to 100 t/h

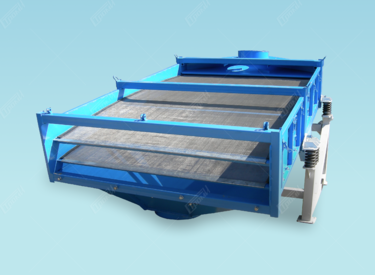

- Vibrating screens (sieves) are used for screening bulk materials with a capacity of 20 to 40 tons per hour. A bezel-free system for installing and tensioning the screening meshes is used in the structure

- Vibrational classifiers are designed to separate dice and particulate materials of medium and high abrasiveness, such as crushed glass, and have a capacity from 5 up to 12 t/h

- The manufactured models of screening package units have either 2 outlets (single screen) or 3 outlets (double screen)

- Rod vibrating screens are used for sorting "complex" bulk materials with a high humidity, high heterogeneity. Such sizing screens are widely used in the lines for processing the imported crushed glass, waste processing, ore sorting